ITPhotonics provides products and solutions for the Industry world as well as for the agricultural sector.

We know that the industry sector is pretty complex: there are so many different products we need to take into consideration, different environments, conditions and purposes. But our Polispec instruments are flexible and open to different types of analysis.

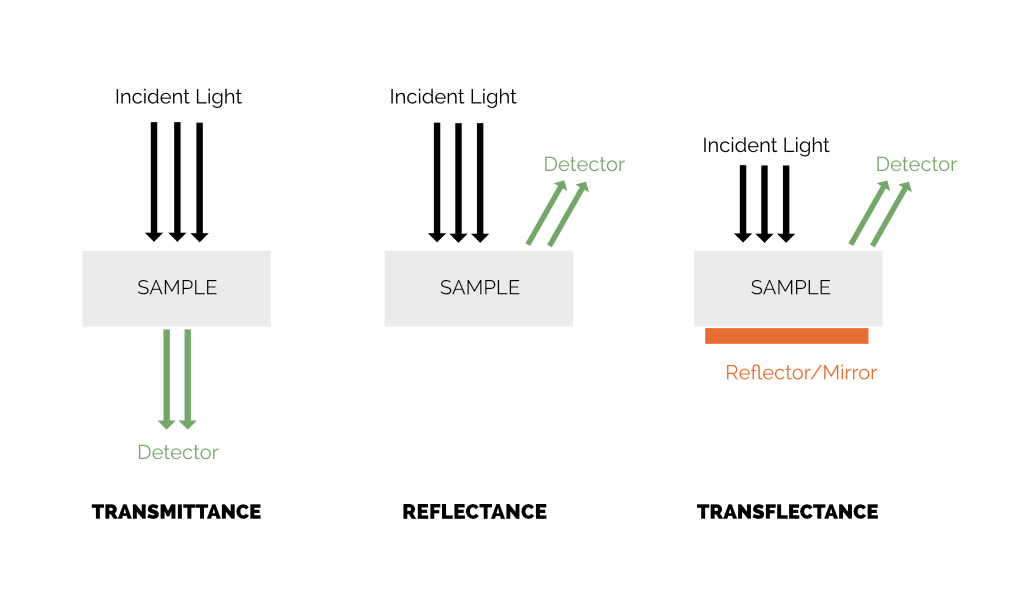

Reflectance, Transmittance or Transflectance?

Three models to analyze products with spectrophotometry

The general aim of spectrometric application is to allow the use of samples as they are. At the same time we present them directly to our instruments without any material pre-treatment. We can carry out extraction of spectral information in different modes, such as transmittance, transflectance and transmittance through scattering medium.

Transflectance is most suited through a thick sample, such as, seeds, slurries, liquids and pastes. Transmission is possible through liquids and films. We use Reflectance predominantly for making measurements off ground or solid materials.

By the way the choice between these 3 models depends not only on the characteristics of the materials but on different complexity of each process as well.

Our PolispecLITE, PolispecVIS-NIT, PolispecNIR and PolispecNIRe instruments can meet all process analysis needs thanks to their flexibility and modularity. So, you can go deep in measurement of any material.

Protection

How to protect our instruments in dangerous environment.

We know that some processes can be dangerous for our instruments. But the whole Polispec line are compatible with the most extreme environments. The metal case gives resistance and excellent dissipation of the heat that the system itself produces.

All the products of the Polispec family are born as complete systems (integrated power supply, lamp, internal references, communication ports…). Furthermore, they’re certified for the highest degrees of protection against liquids and dust as IP68 and IP69K.

Contact or Contactless analysis

Two different application for different environemnts.

Contactless and semi-contact applications differ from contact applications when we analyze the product at a certain distance. This approach is very useful in the following processes:

– We cannot allow the product to get in touch with the measuring system.

– It’s difficult to create the conditions so that we can analyze the product to flow smoothly in front of the scanning window.

All the Polispec systems’ surfaces in contact with the product show different materials to be compatible with the environments of use. It’s also possible to thermally decouple the system from the installation point in order to allow its use even where temperatures are excessive.

We’re going further in details on Polispec instruments characteristics; follow our Linkedin Page to get fresh updates about our products and solutions!